ALL ABOUT AIR BLOWERS .COM

All the Industrial Air Fans & Blowers manufactured are tested at the manufacturers end and performance testing report is generated. It is highly recommended that the user should actualy witness the testing of the air blower and make sure that the air blower performance test results matches the design parameters.

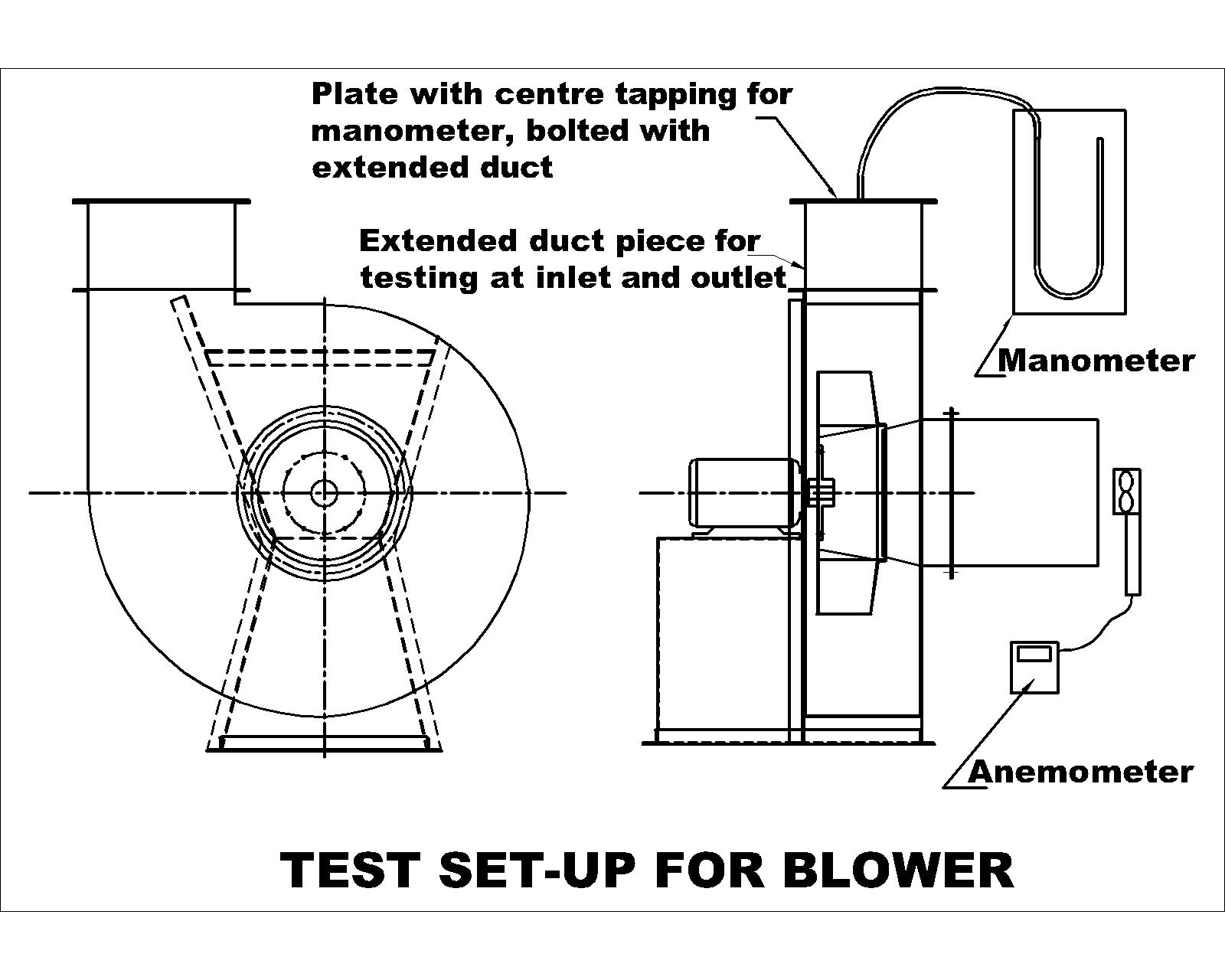

On this page we explain the simplified procedure of

testing air blower

- Connect an extended piece at inlet and outlet of the

Blower. Extended piece length should be atleast the diameter (or

greater length of rectangular outlet). This is to ensure mixing of the

air flow. Please refer fig of Air Blower Test Setup given below

- A plate with tapping at the centre to fix manometer is bolted with extended duct at outlet.

- When the Air Blower is started the plate is completely

bolted such that no air can move out. So the air velocity is neary

zero.

Note the pressure reading on the manometer. Corresponding current

reading of drive motor to be taken.

- Next open some threads of the bolt and loosen the plate. Now air will start passing through the outlet and same amount of air will make entry through inlet side. Measure the velocity of air at the inlet and corresponding Pressure on manometer at the outlet. Measure the motor current Reading.

- Repeat the same procedure and take readings for few more points.

- Make sure to take one reading at designed operating pressure. If the blower design is accurate you will get the desired air flow at the operating pressure. Otherwise also take one reading of pressure at desired air flow.

- So you have Pressure values corresionding to variations in air flow. Plotting the graph of this flow and pressure readings will give you system resistance curve for the particular blower.

- For particular flow and pressure reading you can calculate power consumed from the current readings.

- Theorocial Power vs actual power will give you the efficiency of blower at various operating conditions.

Formulaes to Use

- Air Flow (cfm or m3/sec) = Velocity of Air (fpm or m/sec) / Area of Inlet Opening (ft2/ m2)

- Area of Opening = (3.14/4)x sq. of Diameter

- Motor Power Kw =(1.732 x Voltage x Avg of Current readings

x Power Factor) / 1000